Home /

NEWS /

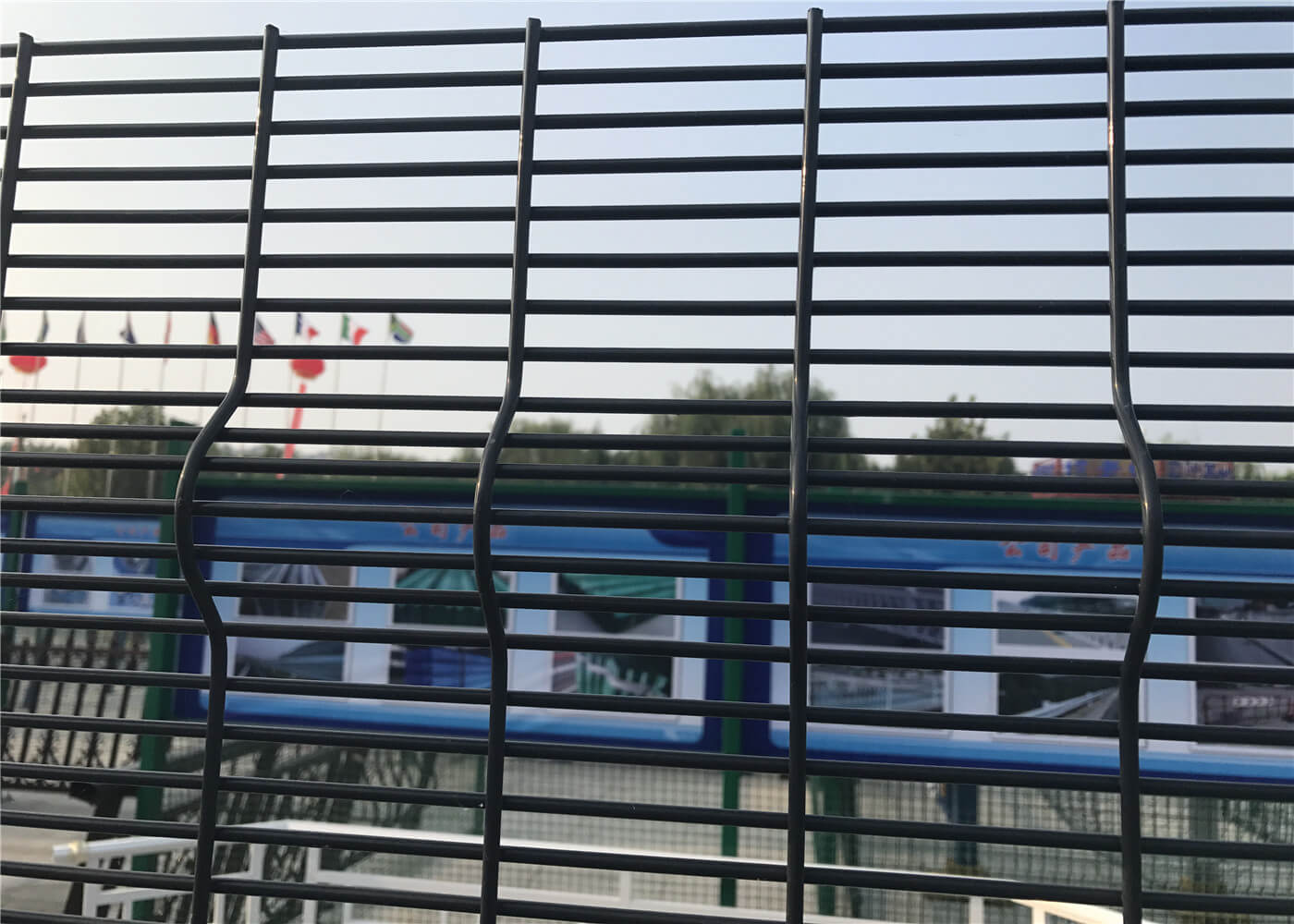

Plastic steel fence welding process

Jun 15, 2019

Briefly describe the welding process requirements of plastic steel fence

The development of industrial production puts forward various requirements for welding skills. For example, in the use of welding products, many requirements such as dynamic load, toughness, high pressure, high temperature, low temperature and corrosion resistance are proposed; . From the structural form of the welded product, the requirements for welding thick-walled parts to fine parts are proposed. From the selection of welding materials, various steel materials and non-ferrous metals are welded (other metals other than steel are called non-ferrous metals). ) requirements.

Specifically, in shipbuilding and marine development, it is required to deal with the welding of large-area panels, large-scale three-dimensional frame structures, and the welding of various low-alloy high-strength steels; in the development of the petrochemical industry, it is required to handle high temperature resistance. Low temperature and pressure vessel manufacturing problems resistant to various corrosive media; in the aerospace industry and space development, it is required to deal with the production of a large number of light alloy structures such as aluminum and titanium; in the heavy machinery industry, it is required to deal with the welding problems of large cross-section members. In the electronics and fine instrumentation industry, it is required to deal with the welding problems of micro-fine parts.

High-speed plastic steel guardrails require fine welds and uniform welds. In short, on the one hand, the development of industrial production puts higher demands on welding skills; on the other hand, the development of scientific skills has opened up new avenues for the advancement of welding skills. In order to meet the needs of China's modernization, welding skills will be more agile and play a more important role in industrial production.

Pre:Traffic fencing function

Next:Lawn fence material