Home /

NEWS /

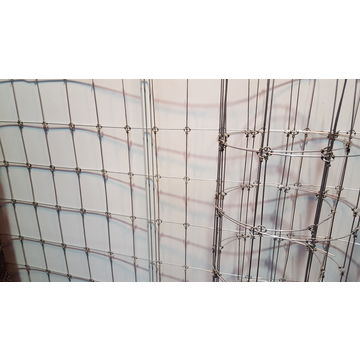

cattle netting

Aug 28, 2019

There are many options in the production process of the bullpen. These options are directly determined by the user, including the wire diameter (between 160 and 350 filaments) and the material of the bullpen net (low carbon wire and high carbon wire). ), surface treatment method (hot-dip galvanizing and electro-galvanizing have many options in the production process of catlle. These optionalities are directly determined by the user, including the wire diameter (between 160 and 350 filaments). The material of the cattle net (low carbon wire and high carbon wire), the surface treatment method (hot dip galvanizing and electrogalvanizing and black iron wire), the composition of these parameters directly determines the physical properties and price cost of the cattle net.

Examples of height and warp root selection:

For the cattle net in the range of 1.1 meters to 1.2 meters, it includes: seven warp threads, eight warp threads, nine warp threads, ten warp threads, all within 1.2 meters in height, sometimes When the customer introduces the customer, I don't know what to do. I don't know what to choose. In fact, there is no mystery here. The customer only needs to clearly choose the purpose. The difference here is only the price difference. The choice of the mesh is different. The fewer the number of net warp threads, the lighter the weight, the lower the price, and the higher the price. The mesh is enlarged as the number of warp threads is reduced. It is also necessary to clarify the purpose of use. Do not blindly pursue low cost and affect the use effect. This requires the customer to customize. These are the selectivity of the height of the bullpen and the number of warp threads.

Pre:The material and weaving characteristics of cattle Net

Next:The difference between cold galvanizing and hot-dip galvanized cow net