A galvanized metal fence is a metal fence that has been coated with zinc to prevent rust and corrosion. This galvanizing process involves immersing the metal railing in a bath of molten zinc, which then forms a protective layer around the metal railing.

The process of galvanizing has been used for centuries to protect metal railings from corrosion. The ancient Egyptians used a form of galvanization to protect their iron tools from rust. Today, electroplating is used in many different industries, including construction, agriculture and manufacturing.

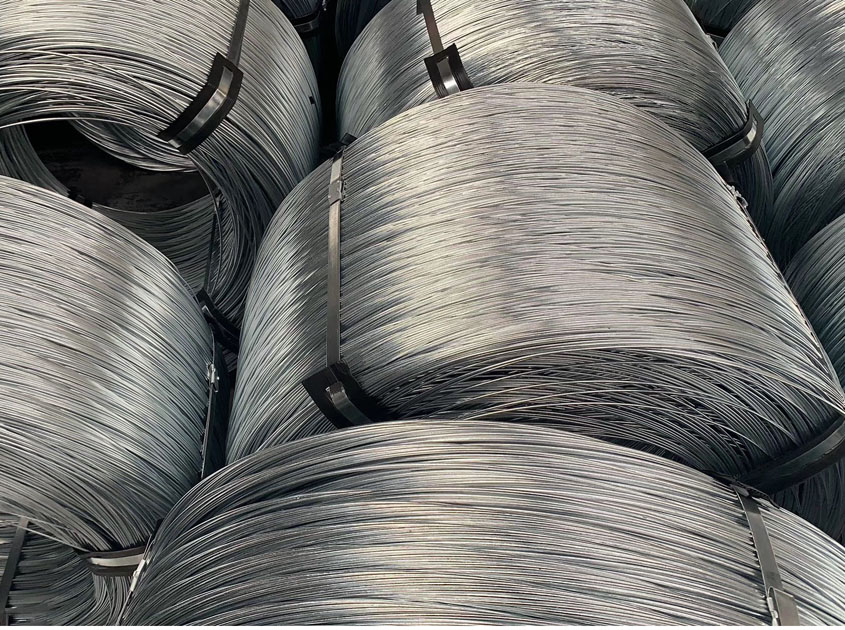

The process of galvanized metal fence starts from the selection of guardrail. Metal guardrails are usually made of mild steel or stainless steel and are cleaned and treated to remove any impurities. This process ensures that the guardrail is free of any contaminants that could interfere with the galvanizing process.

Once the wire is cleaned and treated, it is then dipped into a bath of molten zinc. Zinc forms a protective layer around wires that helps prevent rust and corrosion. The thickness of the zinc coating can vary depending on the application, but is typically between 2 and 5 mils (0.002 and 0.005 inches).

After the wire is galvanized, it is cooled and then inspected to ensure that the coating is uniform and free of defects. The metal railing can then be packaged for shipping.

Galvanized metal fences are commonly used in a variety of applications including fencing, construction and agriculture. It is a durable and long-lasting material that can withstand harsh environments and exposure to the elements.

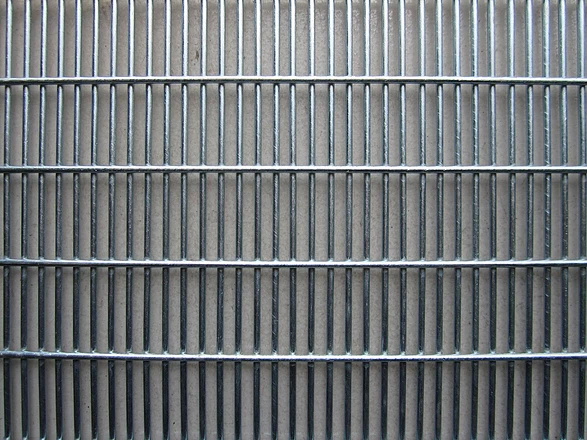

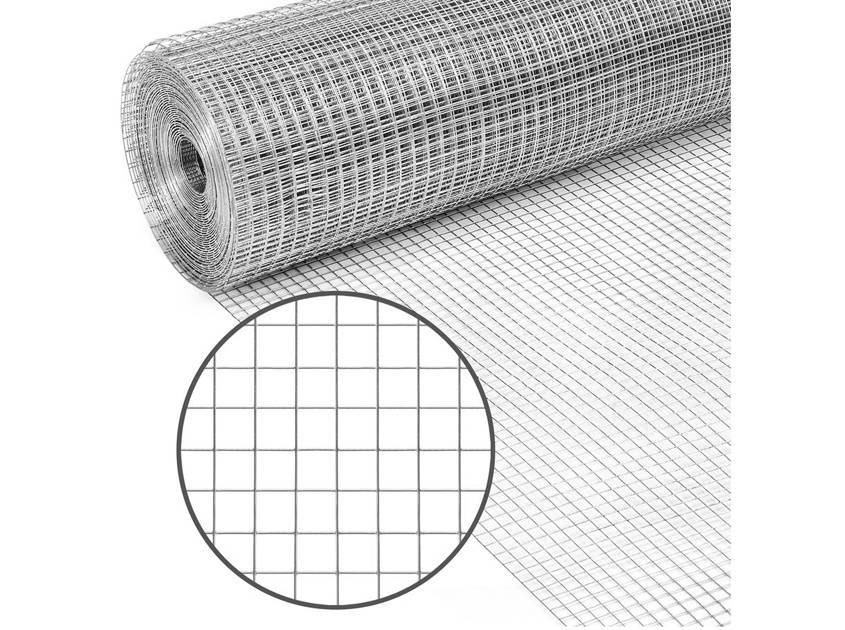

In the construction industry, galvanized wire mesh is often used as reinforcement in concrete structures. Wire mesh helps strengthen the concrete and prevent cracks from forming. It is also used in the production of plasterboard, which is used as a backing material to provide strength and stability.

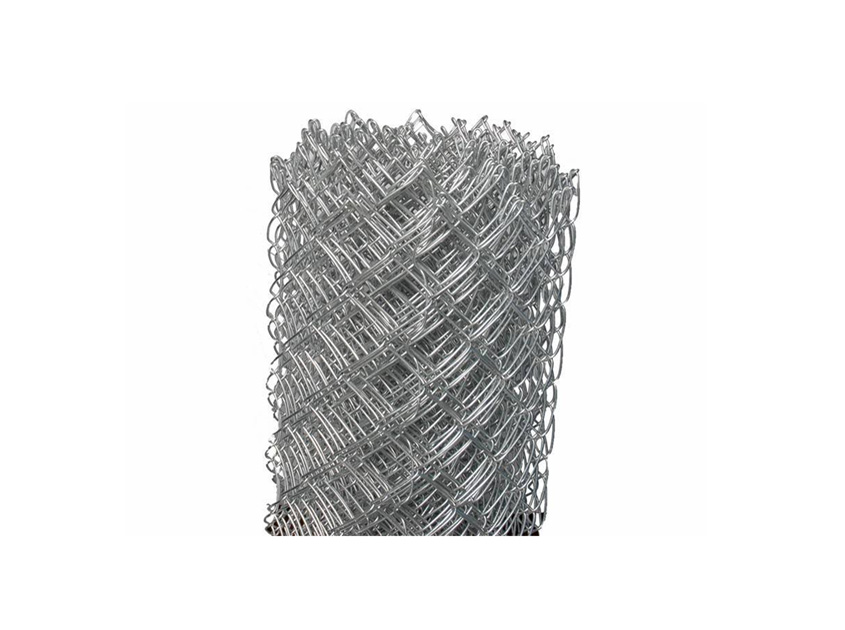

In agriculture, galvanized metal fences are used to construct animal enclosures and to protect crops from pests. Metal railings are strong and durable, making them an ideal material for outdoor use.

Galvanized fence are also commonly used in the production of industrial filters. Metal barriers are woven into a fine mesh and then coated with zinc to create filters that can withstand harsh chemicals and high temperatures.

Overall, the process of galvanizing metal fences is a critical step in producing a durable material. By protecting metal railings from rust and corrosion, galvanizing ensures that metal railings can be used in a variety of applications and environments. Whether used in construction, agriculture or manufacturing, galvanized metal fence is a versatile and reliable material that will continue to be in high demand for years to come.

Pre:How are fence nets stored and shipped

Next:Welded metal mesh is a versatile material, welded mesh fence of linkland

How can South American distributors find suitable fence suppliers? (Professional Procurement Guide)

How to Ensure Fencing Products for the South American Market Meet Local Quality Standards

How to Choose the Right Metal Fence Products for the South American Market?

Chain Link Fence – Flexible, Cost-Effective Fencing Solutions for Global Projects